According to: ASTM D 2693 and ISO 10329

UPDATE 2023! Fluidity resolution 0,1 DDPM!

General Description

The PL 2000 Coal Plastometer is a fully automatic system for determination of fluidity of coal by the Gieseler method according to ASTM D 2639 and ISO 10329 Standards.

Both methods described in the Standards give a relative measure of the plastic behaviour of coal when heated at constant rate, under prescribed conditions.

Fluidity of coal is obtained applying a constant torque on a stirrer placed in a crucible loaded with the coal, heating the crucible in a molten solder bath furnace and recording stirrer movement on a dial drum graduated into 100 divisions, D.D.P.M. (Dial Division per Minute) in relation to increase of temperature.

All the analysis procedure, even up and down movement of the crucible, is automatic: the operator needs only to mount the crucible and to start the system.

The double furnace system productivity is considerably increased due to the reduction of heating and cooling waiting times.

Once started, PL 2000 will preheat the furnace, check the correct loading of the sample, lower the crucible, restore the start temperature, raise the temperature at uniform rate and carry out the fluidity test.

Drum dial movement is recorded by means of an optical encoder with a resolution of 0.1 D.D.P.M.

Furnace temperature together with fluidity readings are displayed and printed out during the test.

Available Versions

The Plastometer PL 2000 is available in Single Furnace (PL 2001) or Double Furnace version (PL 2002).

By the Double Furnace version it is possible to reduce the time wasting waiting for the cooling down of the furnace at the end of the test.

While a fluidity test is running in the first furnace, the second furnace can be preheated at the warm up temperature. At the end of the first test, a second test can be immediately started on the other furnace.

Electronic Unit

The test control is completely devoted to the electronic unit.

Thermal parameters of the test are set by means of a guided set-up procedure; three digital display groups are available to set warm-up temperature (3 digits), temperature rise rate (2 digits) and maximum temperature (3 digits).

A led display group is used to set optional operation set-up. A further four led display group allows system set-up (Diagnostics, Date and Time set, Calibration and Special functions).

During the test two visualisation units show the current temperature (3 digits), and the current fluidity (6 digits). The electronic cage includes a thermal paper printer, 24 characters/line, for status messages and current data printing.

A remote host computer interface (RS232C) is included to allow data logging and/or graphic representation of the results.

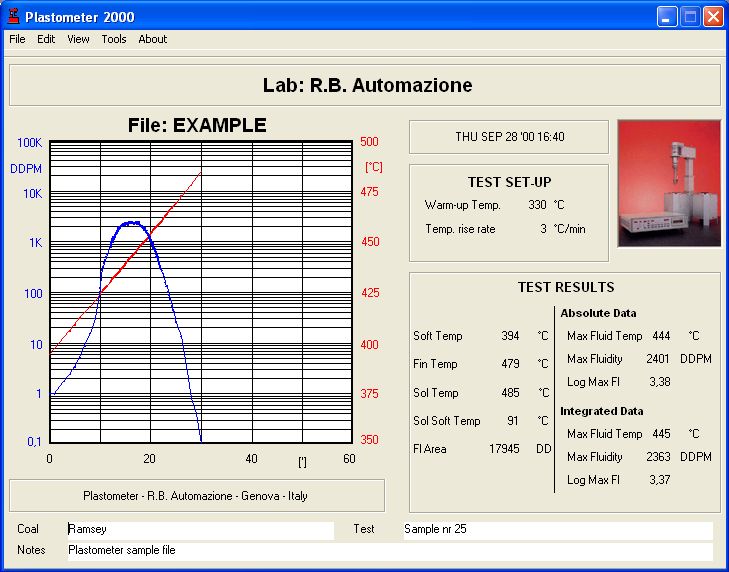

The archiving software Plastometer Data Manager (PDM) is available as option providing an user friendly interface to archive and graphical print out the test results.

PC archiving Software P.D.M.

The system can be connected to an external computer.

All current test data and end of test report are available on a serial port RS 232 in ASCII format. The software “P.D.M. – Plastometer Data Manager” provides friendly interface and support for asynchronous RS232 communications to external PC.

Acquisition, archiving, printing and export of test data, together with test set up and sample identification is fully provided. The software is compatible with Microsoft Windows© environment.

Printer Output

The internal printer returns the results of the test on thermal paper.

Every minute the current values of Time (minutes from the test start), Temperature (°C) and Fluidity (D.D.P.M.) are printed.

At the end of the test, the Test Report is printed according to the international standard.

Specifications | |

Working temperature: | 260 - 600 °C |

Temp rise rate: | 0.5 - 6.0 °C/min |

Stirrer motor speed: | 300 or 1000 rev/min |

Hysteresis brake torque range: | 15 - 100 g*inch |

Solder bath stirrer | in the plastometer head |

Crucible movement | fully automatic |

Temperature display: | °C |

Fluidity display: | 0.1 - 100,000 D.D.P.M. |

Data print interval: | 60 sec |

Alphanumeric printer: | not impact type |

System diagnosys: | Automatic at start up |

Host computer interface | RS 232 C |

Power supply (single furnace): | 230 V / 120 V - 50/60 Hz - 0.8 kVA max |

Power supply (double furnace): | 230 V / 120 V - 50/60 Hz - 1.6 kVA max |

Accessories

The Loading device (PL 2000-90) can be supplied together with the Plastometer PL 2000.

All the consumables (as Crucible, Crucible stirrers, Printer paper etc…) are always available in stock.

Item codes | |

Single Furnace Automatic Plastometer system | PL 2001 |

Double Furnace Automatic Plastometer system | PL 2002 |

Crucible (not included in PL 2001/2 items) | PL 2000-80 |

OPTIONS: | |

PC Archiving Software | PL 2000-64 |

COAL SAMPLE PREPARATION DEVICE | |

Static and Drop Weight loading device | PL 2000-90 |